Dec 1, 2025

Blog advanced materials Conductive Polymers: The Future of Flexible and Smart Electronics

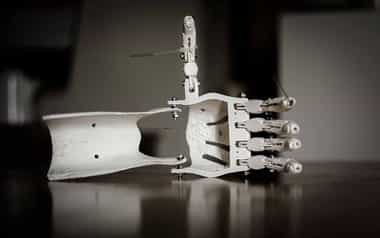

Imagine a material that bends, stretches, twists, and still conducts electricity with remarkable efficiency.

A material as lightweight as plastic, but capable of replacing metal-based components in next-generation electronics.

This is the promise of conductive polymers, a rapidly evolving class of materials reshaping the future of flexible electronics, energy storage, mobility, healthcare, and smart manufacturing.

As industries race toward thinner, lighter, more adaptive devices, conductive polymers are emerging as one of the most disruptive materials of the decade.

Conductive polymers are organic materials that behave like plastics but can conduct electricity similar to metals. Unlike traditional polymers, their molecular structures support the movement of electric charge, making them ideal for electronics that require flexibility, lightweight structures, and tunable conductivity.

Common types of Conductive Polymers include:

These materials bridge the gap between mechanical flexibility and electrical performance, enabling technologies that rigid metals can’t support.

According to BCC Research, the global conductive polymers market is poised for strong expansion, rising from $11.2 billion in 2025 to $17 billion by 2030, at a robust CAGR of 8.6% from 2025 through 2030.

This surge is driven by:

As manufacturing scales and polymer technology improve, conductive polymers will become mainstream materials across high-growth industries.

Modern electronics demand flexibility. Conductive polymers deliver:

Their ability to maintain conductivity under mechanical stress makes them essential for next-gen mobility and health monitoring systems.

Conductive polymers significantly enhance energy systems by improving:

These improvements are critical for EVs, renewable energy systems, and portable electronics, making conductive polymers a key part of global electrification trends.

In electronics handling and automotive interiors, conductive polymers provide safe dissipation of static charge. They act as:

These lightweight alternatives are more durable and cost-efficient than metal-based solutions.

Conductive polymers offer multifunctional coating capabilities, including:

Industries such as aerospace, industrial automation, and advanced manufacturing rely on these properties for enhanced reliability and performance.

The global market for conductive polymers is estimated to grow from $11.2 billion in 2025 and forecast to reach $17 billion by 2030, at a compound annual growth rate (CAGR) of 8.6% from 2025 through 2030.

Electronics & Optoelectronics

Automotive & Mobility

Healthcare & Biomedicine

Energy & Power

Industrial Manufacturing

From smart wearables to EV batteries, conductive polymers are now embedded across the global innovation ecosystem.

Asia-Pacific- The Asia-Pacific region, with manufacturing hubs in China, South Korea, Japan, and Taiwan, drives the most significant and fastest-growing market.

North America - Adoption is highest in high-performance applications, including aerospace coatings, advanced wearable technologies, and Research and Development-Driven energy storage solutions.

Europe - Leads in sustainable materials development, automotive innovations, and high-end electronics. Strong regulatory support fuels growth.

India, Southeast Asia, and Latin America are rapidly adopting conductive polymers in flexible electronics, packaging, and automotive components.

While the potential is enormous, challenges remain:

However, ongoing R&D is driving major improvements:

These advancements will accelerate adoption across industries.

Over the next five years, expect transformative innovations such as:

Conductive polymers are not just improving existing technologies; they’re enabling entirely new product categories.

From flexible electronics to advanced energy storage, conductive polymers are rapidly becoming foundational materials for tomorrow's technologies. With the global market projected to reach $17 billion by 2030, they are shaping the future of mobility, healthcare, consumer electronics, and smart manufacturing.

As industries push for lightweight, adaptable, and sustainable solutions, conductive polymers will continue to drive breakthroughs, powering a smarter, more connected world.

Amrita Kumari is a Senior Executive Email Marketer at BCC Research, with a bachelor’s degree in computer applications. She specializes in content creation and email marketing.

As the world accelerates toward a cleaner, electrified future, battery performan...

Ceramics have been part of human civilization for centuries, from hand-molded po...

In recent years, the construction industry has been undergoing a major transform...

We are your trusted research partner, providing actionable insights and custom consulting across life sciences, advanced materials, and technology. Allow BCC Research to nurture your smartest business decisions today, tomorrow, and beyond.

Contact UsBCC Research provides objective, unbiased measurement and assessment of market opportunities with detailed market research reports. Our experienced industry analysts assess growth opportunities, market sizing, technologies, applications, supply chains and companies with the singular goal of helping you make informed business decisions, free of noise and hype.