Mar 8, 2024

In recent years, the 3D printing industry has witnessed a remarkable surge in innovation, especially in the realm of high-performance plastics. High-performance plastics (HPPs) are advanced materials known for their exceptional mechanical, thermal, and chemical properties, making them highly sought after in the global 3D printing industry. HPPs are expected to be widely used in 3D printing because they have special qualities like resistance to chemicals, high temperature, wear, and abrasion, making them suitable for various industries such as aerospace, automotive, healthcare, oil, and gas, among others. The increasing utilization of 3D printing high-performance plastic across demanding applications promises a growth outlook. BCC Research predicts the global 3D printing high-performance plastics market will hit $520.0 million by 2028, with a projected CAGR of 21.4% from 2023 to 2028. In this blog post, we explore the dynamic landscape of 3D printing high-performance plastics, delving into its market trends, key players, and future prospects.

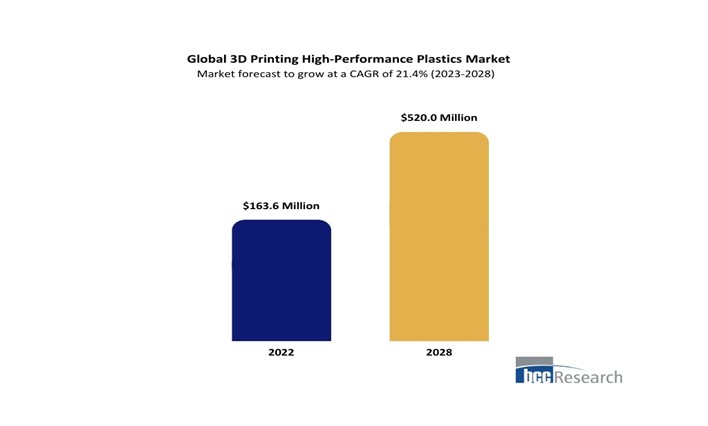

Below is the graph showing the growth in the 3D Printing High-Performance Plastics Market from 2023 to 2028.

The estimated market size of global 3D printing high-performance plastics market is $520.0 million by 2028, with a CAGR of 21.4%.

The future prospects for the 3D printing high-performance plastic market appear favorable as its usage continues to expand in various demanding applications. The growing awareness of 3D printing and consistent innovation in material science are also expected to contribute to market growth. The market size is forecasted to reach $520.0 million by 2028, with a Compound Annual Growth Rate (CAGR) of 21.4% for the period 2023-2028, driven by key market drivers such as the rise in HPP demand from the medical sector, the advantage of HPPs over metal alternatives in 3D printing, and the proliferation in demand for lightweight 3D printing materials from challenging industries. In conclusion, these factors position the 3D printing high-performance plastic market for significant growth in the coming years.

Consider becoming a member of the BCC Research library and gain access to our full catalog of market research reports in your industry. Not seeing what you are looking for? We offer custom solutions too, including our new product line: Custom Intelligence Services.

Contact us today to find out more.

Heena Singh is a Senior Executive Email Marketer at BCC Research, with a master’s degree in computer applications. She specializes in content creation and data analytics.

Biophotonics: Technologies and Global Markets (PHO024B)

Global Trade: A Strategic Shift The global trade environment is undergoing a dra...

The global demand for cutting-edge materials continues to rise, and at the foref...

We are your trusted research partner, providing actionable insights and custom consulting across life sciences, advanced materials, and technology. Allow BCC Research to nurture your smartest business decisions today, tomorrow, and beyond.

Contact UsBCC Research provides objective, unbiased measurement and assessment of market opportunities with detailed market research reports. Our experienced industry analysts assess growth opportunities, market sizing, technologies, applications, supply chains and companies with the singular goal of helping you make informed business decisions, free of noise and hype.