Every year, the United Kingdom produces an estimated 300,000 tons of expanded polystyrene waste (think of those “peanuts” you used to pack last year’s holiday gifts), enough to fill 15,000 Olympic swimming pools. Surely there’s no medal awarded for that.

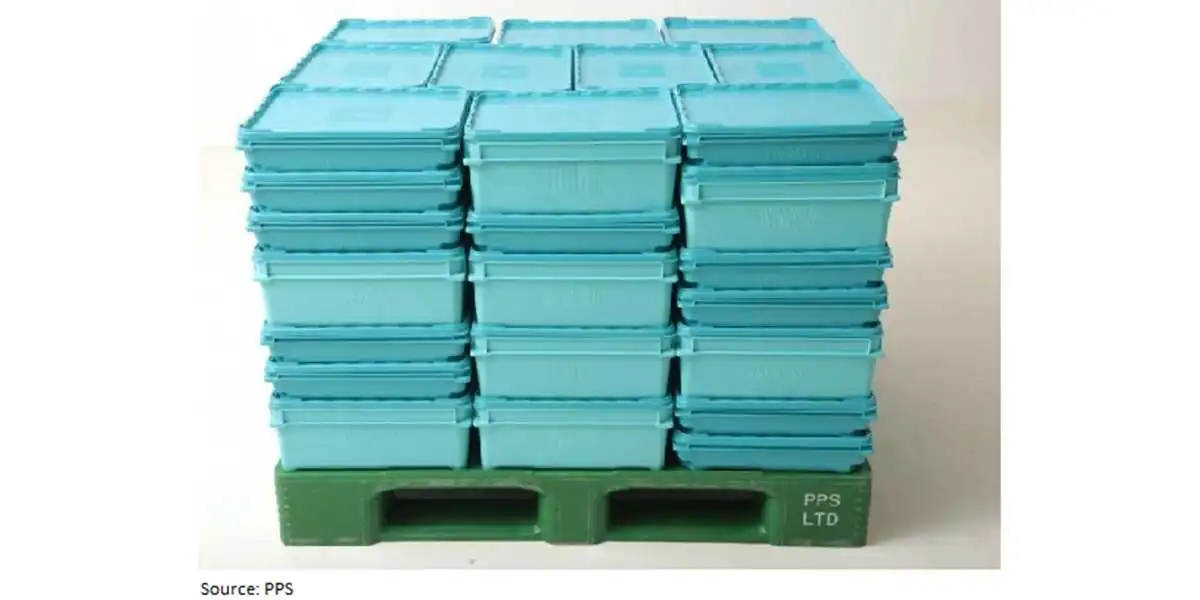

In an effort to lower waste and carbon footprint, at least in the seafood packaging industry, a company has developed a reusable hygienic plastic tray intended for full supply chain distribution of fresh fish and seafood, from dockside to supermarket.

“Re-Fresh” boxes were specifically manufactured to be reused in a typical seafood supply chain for up to 10 years, and then can be 100% recycled after use, according to

PPS. The company, which provides returnable plastic packaging and container solutions, says although designed for use in the seafood industry, the boxes can be used to package meat, poultry, as well as other fresh foods and even pharmaceutical products.

The product exemplifies how emerging packaging technologies can improve the sustainability and reliability of products, as well as aid in managing their inventory. The flexibility offered by packaging technologies help in product storage, transportation and shipment. Modern industries have now begun to explore the advantages of packaging technologies in their production and processes. This has led to a steady market for them.

WHAT ARE PACKAGING TECHNOLOGIES?

Packaging exists in many forms. It can be any wrapping material that is used around a consumable, either food or beverage,

explains BCC Research analyst Shalini S. Dewan. The packaging market is a dynamic market that depends mostly on innovations and advancements. Due to the sustained dependency of the food and beverage industry on packaging, a lot of research and innovations have paved the path for the development of the advanced packaging technologies.

“The key focus of the modern day packaging industry is to provide secure, reliable, easy to handle, foods and beverages to consumers through various packaging techniques, namely active, controlled and intelligent methods,” Dewan says. “Packaging technologies like that seen in the Re-fresh box help in product storage, transportation and shipment. For instance, the sustainability gained from packaging used for food and beverages is valued from the perspective of safety, recyclability and as a means to reduce food waste.”

WHAT ARE ACTIVE, CONTROLLED AND INTELLIGENT PACKAGING METHODS?

Active packaging is an advanced packaging technique that protects the packaged food or beverage by interacting with the consumables inside the packaging. Its techniques involve moisture control, oxygen scavenging, incorporation of ultraviolet ray blockers and antimicrobial agents.

Controlled packaging facilitates the maintenance of ambient atmosphere by either controlling or modifying the gas present inside the package.

Intelligent packaging is the advanced packaging technology most suitable for today’s retail sectors, super stores and more. It facilitates the monitoring of food freshness and quality through time/temperature indicators and freshness indicators. This technology also offers loss prevention and asset protection.

The ability to retain product integrity while reducing packaging waste are key features of the Re-fresh boxes. Available in 3kg and 6kg in volume sizes, the boxes offer a patent-pending, re-sealable leak-proof lid design. The lids prevent leakage yet can be removed with ease when opening the boxes, a boon for transportation and delivery into retail stores.

Both sized boxes have the same footprint, but two 3kg boxes equal the height of one 6kg box, which maximizes loads because they can be stacked to save space while protecting the product. When empty, the reusable boxes can be nested together, saving space and eliminating waste.

The boxes are made from food grade high impact copolymer polypropylene.

According to Dewan, global packaging market revenues totaled nearly $42.5 billion in 2014. BCC Research estimates this market will increase from $43.3 billion in 2015 to nearly $48.3 billion by 2020 at a compound annual growth rate (CAGR) of 2.2% through 2020, she says.