Apr 1, 2024

As people live longer and live more actively, the demands on medical equipment have increased, too. Increasingly, innovative medical applications place further importance on the success of the materials they use. When patients’ health, mobility and comfort are involved, reliability and durability are crucial.

In the health care sector, wearable medical devices increasingly are called upon to perform a variety of important tasks, such as monitoring vital signs or delivering drugs. The tasks they perform are highly diverse, as are the demands imposed on the materials used to make them. Their popularity continues to grow as does the need for materials that satisfy the unique requirements of these devices.

The obvious aging of the U.S. population, continuing cost-reduction pressures in the healthcare field, advances in polymer performance, introduction of new and often life-saving devices and the ever-present environmental/disposable/Non disposable medical devices.

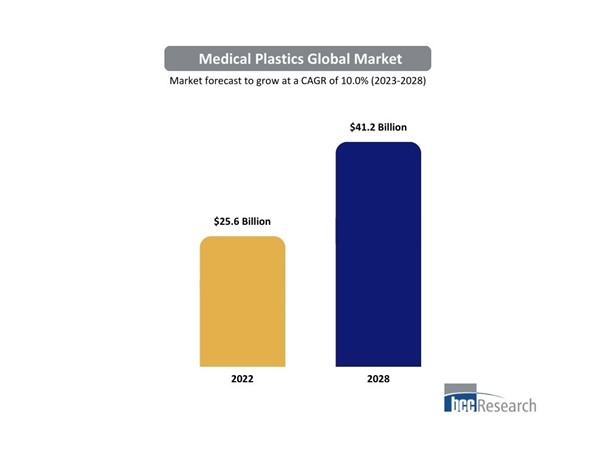

The medical plastics global market has advanced, with the global market value projected to hit $25.6 billion in 2023 to reach $41.2 billion by 2028, at a compound annual growth rate (CAGR) of 10.0% from 2023 through 2028. The increasing use of these medical plastics continues transforming the health market, with plastic medical products replacing medical instruments originally fabricated with ceramics, steel, or glass where applicable. This is because they are more cost-effective, durable, lightweight, and compatible with various manufacturing processes.

The global market for medical plastics is estimated to increase from $25.6 billion in 2023 to reach $41.2 billion by 2028, at a compound annual growth rate (CAGR) of 10.0% from 2023 through 2028.

Evonik is a specialty chemicals company that offers a range of materials for medical applications, including biocompatible polymers, implantable materials, and drug delivery systems. The company focuses on developing innovative solutions tailored to the needs of medical device manufacturers, contributing to advancements in patient care and treatment outcomes.

Celanese Corporation is a global chemical company that produces a variety of chemical products, including plastics, fibers, and other specialty materials. The company was founded in 1918 as the American Cellulose Corporation, later renamed Celanese Corporation in 2005.The company operates its manufacturing facilities in North America, Asia, and Europe.

Eastman Chemical Company is a global specialty chemical company headquartered in Kingsport, Tennessee, United States. It was founded in 1920 and has since grown to become a leading producer of a wide range of advanced materials, including specialty plastics, chemicals, fibers, and additives.

Sumitomo Chemical Co., Ltd. is a global chemical company headquartered in Tokyo, Japan. It was founded in 1913 and has since grown to become one of the largest chemical manufacturers in the world. Sumitomo Chemical operates across a wide range of sectors, including petrochemicals, energy and functional materials, IT-related chemicals, health and crop sciences, and pharmaceuticals.

Toray Industries, Inc. is a multinational corporation headquartered in Tokyo, Japan. Established in 1926, Toray has grown to become one of the world's leading producers of advanced materials and chemicals. Toray develops and manufactures a diverse range of healthcare products, including medical textiles, surgical materials, pharmaceuticals, and diagnostic equipment.

The future outlook for the medical plastics industry appears promising, with the global market expected to surge to $41.2 billion by 2028, boasting a robust compound annual growth rate (CAGR) of 13.5% from 2023 to 2028. The medical plastics market continues to evolve in response to dynamic healthcare needs and technological advancements. With a growing emphasis on patient safety, performance, and sustainability, medical plastics are poised to play an increasingly integral role in shaping the future of healthcare delivery. By embracing innovation, fostering collaboration, and staying attuned to market trends, stakeholders can capitalize on the myriad opportunities presented by this thriving sector.

Consider becoming a member of the BCC Research library and gain access to our full catalog of market research reports in your industry. Not seeing what you are looking for? We offer custom solutions too, including our new product line: Custom Intelligence Services.

Contact us today to find out more.

Amrita Kumari is a Senior Executive Email Marketer at BCC Research, with a bachelor’s degree in computer applications. She specializes in content creation and email marketing.

Biophotonics: Technologies and Global Markets (PHO024B)

Global Trade: A Strategic Shift The global trade environment is undergoing a dra...

The global demand for cutting-edge materials continues to rise, and at the foref...

We are your trusted research partner, providing actionable insights and custom consulting across life sciences, advanced materials, and technology. Allow BCC Research to nurture your smartest business decisions today, tomorrow, and beyond.

Contact UsBCC Research provides objective, unbiased measurement and assessment of market opportunities with detailed market research reports. Our experienced industry analysts assess growth opportunities, market sizing, technologies, applications, supply chains and companies with the singular goal of helping you make informed business decisions, free of noise and hype.