Bangalore-based Indian Institute of Science (IISc) researchers and Steer Engineering Pvt. Ltd, Bangalore, have designed a membrane which eliminates 99% of bacterial contamination from water.

The development improves upon the

antibacterial membrane the researchers developed in 2014. The new, improved membrane allows higher flow rate across it and kills nearly 99 per cent of E. Coli present in water.

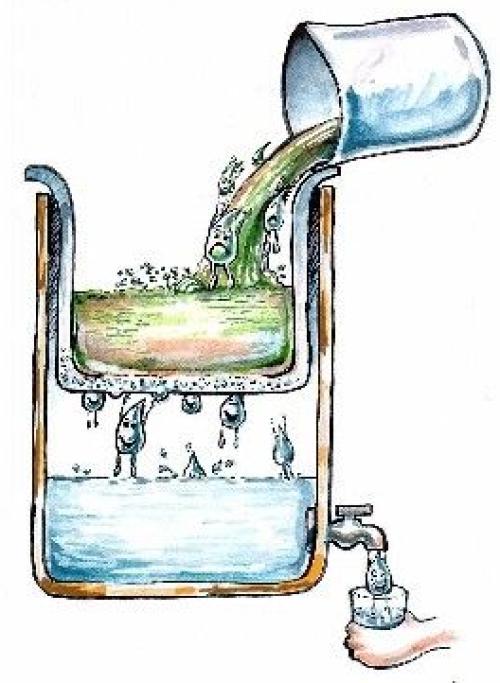

The water purification membrane is capable of filtering out objects greater than one micron size while also killing E. coli bacteria. The membrane, made of polyethylene, also prevents biofouling- accumulation of micro-organisms on the membrane. Biofouling blocks the membrane and increases the overall time, cost and energy required for water purification.

WATERBORNE DISEASES, ILLNESSES AND DEATHS: AN EPIDEMIC

Water-related diseases are a leading cause of death worldwide. Hundreds of millions of people don't have access to improved sources of drinking water, leaving them at risk for water-, sanitation-, and hygiene- (WASH) related diseases.

Worldwide in 2010, 801,000 children died from diarrheal illnesses, most of which are caused by unsafe water, poor sanitation, and inadequate hygiene, according to the

World Health Organization. Devastating epidemics of cholera like the 2010-2011 outbreak in Haiti that caused more than 500,000 cases of illness and 7,000 deaths, are only the “tip of the iceberg,” as most waterborne diseases, illnesses, and deaths are never reported, according to a

report published in the New England Journal of Medicine.

Global demand for clean water and reuse of environmental sources is expected to increase by 20% during the next two decades. Market forecasters are expecting Asian, as well as North America and East European, countries to lead global efforts of environmental protection services and projects.

'TORTUOUS' BIGGER PORES KEY TO MEMBRANE'S STRUCTURE

Responding to these challenges requires a spectrum of interventions. The prevention or minimization of water pollution is critical to improving drinking water quality.

Led by Suryasarathi Bose, the study's author and a professor with IISc's Department of Materials Engineering, the team produced a more permeable structure by creating pores that are bigger in size and more interconnected than the membrane it developed two years.

By mixing equal amounts of polyethylene (PE) and polyethylene oxide (PEO), bigger and more "tortuous" pores were produced. Because PEO is soluble in water unlike PE, pores tend to form when the membrane containing PEO is dipped in water. In the precursor membrane, the researchers used a tiny amount of PEO and sheared it at high speed to produce tiny droplets of PEO to create smaller pores.

“We took equal amounts of PE and PEO so we get more tortuous pores upon removal of PEO. This is not possible if we take tiny amounts of PEO,” Prof. Bose

explains.

Besides being tortuous, the pores also are asymmetrical—their dimensions are not uniform throughout. At some places the pores get so narrow that they tend to be as small as the micro-holes of the membrane's predecessor. According to Bose, who tells

The Hindu: “If the pores are asymmetrical then bacteria and other contaminants will have a tougher path to pass through, so they will get trapped.”

GRAPHENE OXIDE SLICES AND DICES CONTAMINANTS TO DEATH, LITERALLY

To render the membrane antibacterial, graphene oxide was mixed with the two polymers and the graphene oxide was made functional with amine groups. “Earlier the antibacterial effect was not significant as graphene oxide was embedded inside the membrane. But now we have made it more effective by anchoring graphene oxide on the surface of the membrane,” Bose says.

Unlike other biocidalagents like silver, because graphene sheets are non-leaching and non-depleting, they're safe for use in filtration procedure. The team tested the antibacterial activity of the membrane on E. coli, a common contaminant of water. The antibacterial activity of graphene oxide is primarily due to its sharp edges. The scissoring and knife-cutting effects of graphene oxide pierces and destroys the bacterial cell wall of contaminants, leading to their death.

The graphene oxide sheet coating won't clog the pores of the membrane, either. Thus, it improves membrane efficiency without compromising the flow rate.

The results of the study were published in

Nanoscale.