An Israel-based electronics printing tech firm has completed the development of a software package for integration in the company's 3-D printer. The DragonFly 2020 3-D printer, currently in development, will use proprietary inks and the integrated software to quickly create fully functioning printed circuit board (PCB) prototypes.

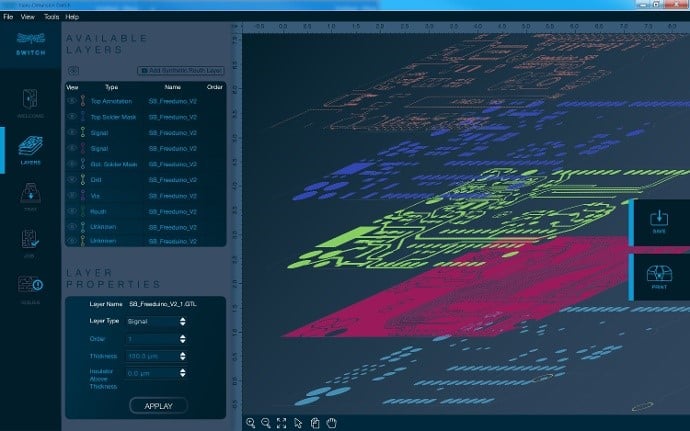

The software package, called “Switch”, was developed by

Nano Dimension. According to the company’s

news release, the software supports customary formats in the electronics industry such as Gerber, VIA and DRILL files. Users can edit and prepare multilayer 3-D files for printing. Many parameters can be adjusted, such as layer thickness, conductor width, layer order, punching and rotation options as well as the shape or object outline. In addition, the software optimizes the printing process by maximizing the printer’s 20 x 20 cm printing surface.

WHAT ARE PRINTED CIRCUIT BOARDS?

Printed circuit boards are undoubtedly the main components of the semiconductor-device revolution,

says BCC Research analyst Kaustubha Parkhi.

“Printed circuit boards (PCBs) are ubiquitous markers of the semiconductor revolution although they predate the advent of modern-day electronics by several decades,” he says. “PCBs provide a platform for the placement and interconnection of diverse components, modules and subsystems in electronic devices. They’re simpler to visualize and easier to understand technologically compared to their sophisticated components.”

The abovementioned conducting features are typically etched from conducting material like copper. Parkhi also

notes that the base substrate of PCBs is non-conducting. Etching and lamination are the two key processes required for fabricating PCBs with the desired conducting pattern spanning the desired number of layers.

He adds that their increasing appeal to the innovative segments goes hand-in-hand with the increasing adoption of electronics and ICT constructs in various industries and verticals in both the business and consumer segments, including the 3-D printing sector.

3-D PRINTING TECHNOLOGY: HARDWARE MEETS SOFTWARE

Amit Dror, Nano Dimension CEO, notes that the development of the initial version of the 3-D printer software “presents a new dimension for creating and designing electronic circuits.“

“In order to minimize production time, Nano Dimension strives to provide its customers a comprehensive solution to 3-D print multilayer PCB prototypes. Our novel 3-D printer, advanced conductive and dielectric nano-inks, and advanced software package for the management, editing and printing of electronics files…[all] are designed to allow the engineer to create the production files for automat 3-D printing, with no intermediate files,” he says. “It’s now easy to ‘Switch’ from Gerber to 3-D files.”

Nano Dimension, founded in 2012, focuses on the development of advanced 3-D printed electronics systems and advanced additive manufacturing. Its products combine three advanced technologies: 3-D inkjet, 3-D software and nanomaterials.