Sep 13, 2024

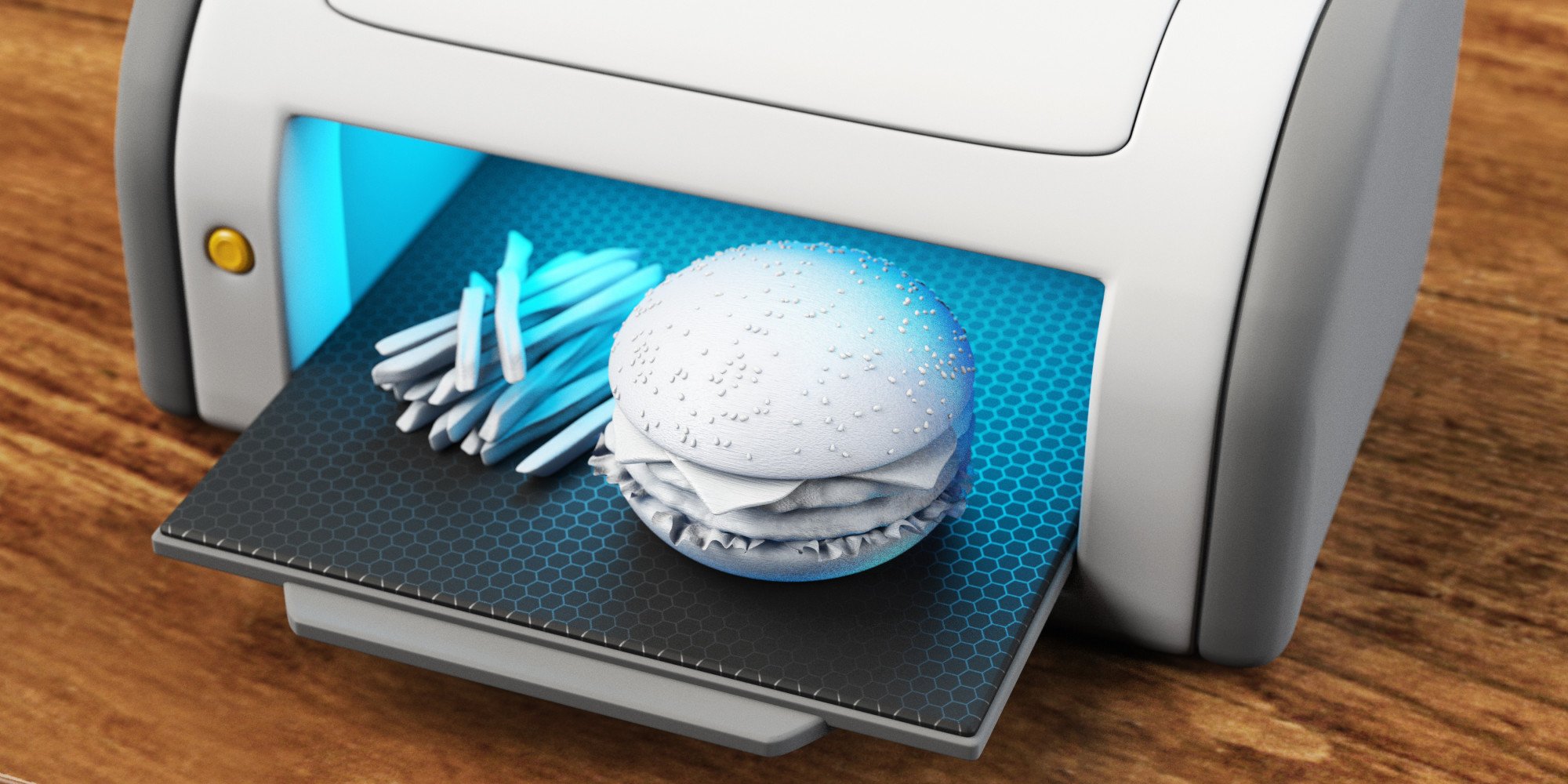

Blog Energy & Sustainability How 3D Printing is Revolutionizing Global Industries

The 3D printing industry has completely transformed manufacturing. It makes it possible to create intricate, personalized products using an additive process that constructs objects layer by layer from digital models. Previously seen as a specialized technology, 3D printing has emerged as a game-changing instrument in various sectors, including consumer products, aerospace, healthcare, and automotive. This blog examines the major developments, growth forecasts, and trends influencing the 3D printing industry and its effects worldwide.

According to BCC Research, the global market for 3D printing is expected to grow from $18.0 billion in 2024 to $29.4 billion by the end of 2029 at a compound annual growth rate (CAGR) of 10.2% during the forecast period of 2024 to 2029.

3D printing, also known as additive manufacturing, is a process where materials such as plastics, metals, or ceramics are layered to create a three-dimensional object based on a digital design. Unlike traditional subtractive manufacturing methods, where materials are cut away to create a product, 3D printing builds items up layer by layer, allowing for highly detailed and complex designs.

Several factors are driving the rapid expansion of the 3D printing market:

The global market for 3D printing is expected to grow from $18.0 billion in 2024 and is projected to reach $29.4 billion by the end of 2029, at a compound annual growth rate (CAGR) of 10.2% during the forecast period of 2024 to 2029.

The 3D printing market is growing across multiple industries, each leveraging the technology for different applications:

Several companies are leading the way in 3D printing innovations:

Despite the enormous potential that 3D printing presents, the sector faces obstacles. Adoption may be slowed by issues with intellectual property protection, poor material alternatives, and the high initial price of industrial-grade printers. In addition, adopting 3D printing technologies for design and operation requires qualified personnel.

Nonetheless, these difficulties offer opportunities for creativity. As material options increase and printer prices decline, more companies will use 3D printing. Technological developments in cybersecurity will also improve intellectual property protection, making it safer for businesses to digitize their manufacturing processes.

3D printing has a promising future since it can create new business models and change entire sectors. As businesses increasingly use this technology, manufacturers, designers, and academics working together will push the boundaries of what is feasible.

In the upcoming years, 3D printing will help intelligent factories produce goods on demand and with mass customization. As technology advances, sustainable manufacturing and bioprinting breakthroughs are also expected.

The demand for creative, affordable, and customizable solutions across various industries is expected to propel the worldwide 3D printing industry to significant development. As technology breakthroughs open up new possibilities, 3D printing will become increasingly important in determining the direction of manufacturing, healthcare, and other industries. Accepting this disruptive technology will allow companies to maintain their competitiveness and adapt to changing consumer needs, making it a crucial instrument for manufacturing in the future.

Consider becoming a member of the BCC Research library and gain access to our full catalog of market research reports in your industry. Not seeing what you are looking for? We offer custom solutions too, including our new product line: Custom Intelligence Services.

Contact us today to find out more.

Sandeep is a Senior Executive in Marketing Operations at BCC Research, proficiently serving as a graphic designer and content creative specialist. His expertise extends to AutoCAD and Revit, and he has made valuable contributions to the event industry with his design skills.

Electrical switches—devices that control the flow of electricity—are the backbon...

As the world accelerates toward net-zero emissions, hydrogen, and ammonia have e...

Hydrogen technology is widely used across industries like glass, fertilizer, met...

We are your trusted research partner, providing actionable insights and custom consulting across life sciences, advanced materials, and technology. Allow BCC Research to nurture your smartest business decisions today, tomorrow, and beyond.

Contact UsBCC Research provides objective, unbiased measurement and assessment of market opportunities with detailed market research reports. Our experienced industry analysts assess growth opportunities, market sizing, technologies, applications, supply chains and companies with the singular goal of helping you make informed business decisions, free of noise and hype.