In recent years, there has been tremendous growth, both technologically and in terms of demand, in electronic devices and systems. The technological progress has come on two main fronts: increased functionality on a single device unit and miniaturization of each unit. Both of these developments have increased the need for thermal management technologies.

Toward that end, researchers at Chalmers University of Technology have

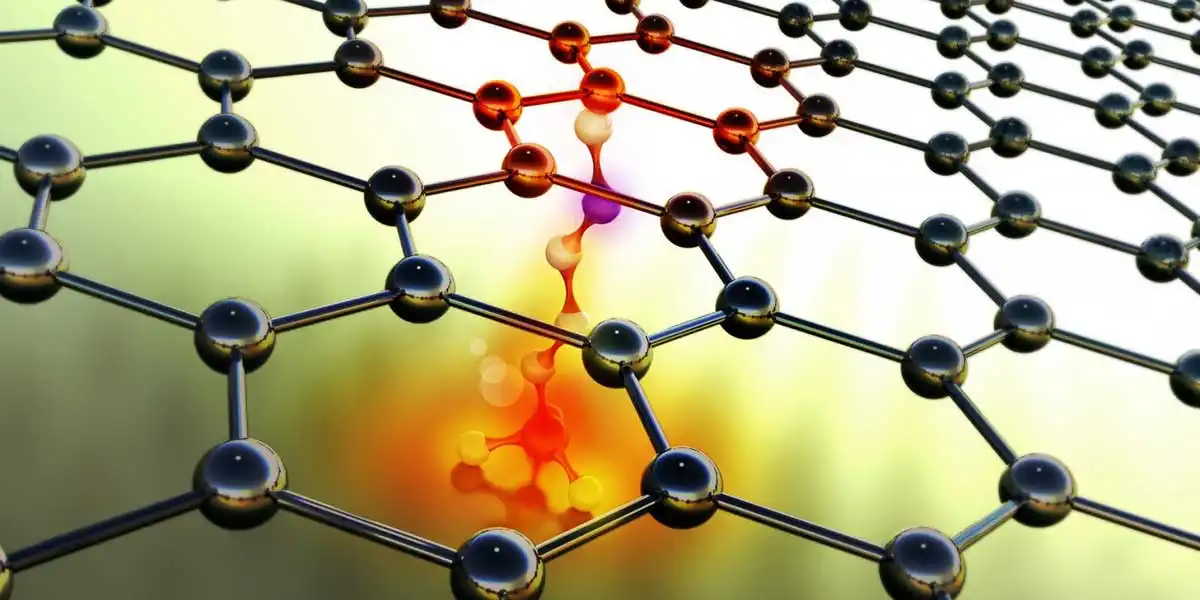

developed an efficient way of cooling electronics by using functionalized graphene nanoflakes.

"Essentially, we have found a golden key with which to achieve efficient heat transport in electronics and other power devices by using graphene nanoflake-based film. This can open up potential uses of this kind of film in broad areas, and we are getting closer to pilot-scale production based on this discovery," says Johan Liu, Professor of Electronics Production at Chalmers University of Technology in Sweden.

The researchers studied the heat transfer enhancement of the film with different functionalized amino-based and azide-based silane molecules. They found that the heat transfer efficiency of the film can be improved by over 76% by introducing functionalization molecules, as compared with a reference system without the functional layer, which greatly reduced contact resistance.

According to the study, molecular dynamic simulations and ab initio calculations showed that the functional layer constrains the cross-plane scattering of low-frequency phonons, which, in turn, enhances in-plane heat-conduction of the bonded film by recovering the long flexural phonon lifetime. The results suggested potential thermal management solutions for electronic devices.

IMPORTANCE OF THERMAL MANAGEMENT

As a result of the widespread introduction of microelectronics, together with the increasing

demands on their functionality and reliability, thermal management has become an important issue in almost every branch of industry, including professional and consumer electronics systems as well as automobile electronics, electronic lamps, and domestic appliances. The need to cool complex electronic systems results from many factors, including those described below.

POWER DISSIPATION

“Devices have to deliver greater functionality within a higher-density, lower-profile package,”

says Andrew McWilliams, a BCC Research analyst. “Boards have to accommodate a larger number of components and are subjected to finer spacing rules. Shelves have to house more boards that are slotted at a lower pitch. Frames have to pack everything within a smaller footprint.”

From a thermal management perspective, there is a significant price to pay for this increase in functionality. Device operating frequency and gate count are increasing rapidly, dissipating greater amounts of power as heat. The buildup of excess heat is the major cause of failure in electronic systems.

The figure below illustrates the major causes of electronic failure.

TYPES OF THERMAL MANAGEMENT PRODUCTS

The thermal management arena can be segmented into four main product categories—hardware, software, thermal interfaces, and thermal substrates—that elucidate the characteristics of this industry.

These categories can be defined in general terms as follows:

Hardware. The hardware product segment includes metal or composite material products that are usually the primary heat exchanger in a thermal management assembly. The most recognizable of these products is the heat sink. This group includes conventional metal heat sink and enclosure fans, and some less familiar products more recently introduced into commercial electronics, such as fan sinks, heat pipes, cold plates, and thermoelectric coolers. The market for these active and passive cooling solutions is well established. The hardware market segment has benefited the most from the advancement of technology in the electronics industry.

Software. This is primarily a set of design, modeling, and analysis tools used by engineers and system designers to test, design, and analyze thermal component productivity and features. These tools have had a significant influence on the development of thermal management technology.

Interfaces. These products go between a heat sink and the device to be cooled. They are just as often associated with the board-level heat sink as the package-level heat sink. Their function is to improve the thermal transfer in the joint between the heat sink and the device to be cooled by increasing or securing the area of contact between the two surfaces.

Substrates. Substrates aid in managing heat at the package level. These are the foundation of an IC, or a planar component of an electronic package or module.

McWilliams projects the total global thermal management revenues to reach nearly $11.2 billion in 2016 and $14.7 billion in 2021, representing a five-year CAGR of 5.6%.

STUDY SUGGESTS FUNCTIONALIZATION MOLECULES HOLD KEY TO HEAT DISSIPATION

Heat dissipation in electronics and optoelectronics can cause a severe bottleneck in the further development of systems in these fields, for which Liu’s study offers a possible remedy.

Liu and his research colleagues studied a number of molecules that were immobilized at the interfaces and at the edge of graphene nanoflake-based sheets forming covalent bonds.

They also probed interface thermal resistance by using a photo-thermal reflectance measurement technique to demonstrate an improved thermal coupling due to functionalization.

"This is the first time that such systematic research has been done. The present work is much more extensive than previously published results from several involved partners, and it covers more functionalization molecules and also more extensive direct evidence of the thermal contact resistance measurement," Liu says.