The carbon capture segment of the global membrane technology market records another entry into its fold. Whitefox Technologies announced last month it plans to enter the carbon capture and storage sector (CSS), with plans to build a demonstration unit, according to Madeleine Cuff.

The UK-based firm's chief executive Gillian Harrison told BusinessGreen that the firm will use its membrane technology, developed for removing water from solvents like ethanol, for the separation of gasses for CCS.

Harrison tells Cuff that membrane technology has great potential for removing carbon dioxide from the atmosphere, but that its final success rests on how to usefully redeploy the carbon.

"I would prefer to see people coming up with really good solutions for using CO2, rather than sequestering it," Cuff quotes Harrison. "I think then you can start to see some fantastic opportunities. I think if we just rely on sequestering it then that's going to limit the growth."

WHAT IS MEMBRANE TECHNOLOGY?

Membranes generally are thin sheets or surface films, natural or man-made, with apertures through which small molecules may pass while larger ones are retained. At its most basic, a membrane serves as a sieve, separating solids from liquids forced through it,

says BCC Research analyst Susan Hanft.

Membranes made from various materials (mainly synthetic polymers) can efficiently filter particles down to the size range of molecules or ions. The separated chemicals are not destroyed, but are concentrated to facilitate reclamation. Membranes are called semipermeable because some substances will pass through, while others will not, Hanft explains. “Usually, small ions, water, solvents, gases, and other very small molecules can pass easily through a membrane, while other ions and macromolecules, like proteins and colloids, are retained.”

MEMBRANE-BASED CARBON CAPTURE TECHNOLOGY

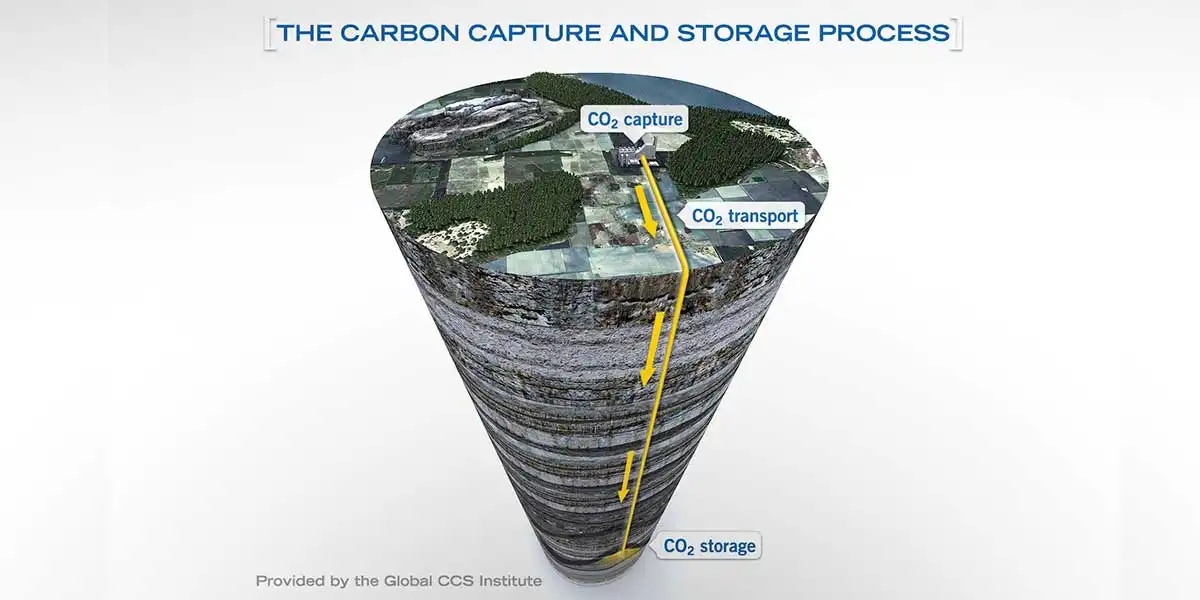

Gas separation using membranes is emerging as an important tool for capturing CO2 from gas streams since the approach offers significant advantages over conventional gas separation processes, according to Hanft. Currently, there are no commercial operations separating CO2 from flue gases, but membranes are employed in enhanced oil recovery operations to recycle CO2 from associated gases and to remove CO2 from natural gas and biogas or landfill gas.

Two types of membranes. Carbon capture involves two membrane types: gas separation membranes and gas absorption membranes.

Gas separation membranes. These membranes rely on a difference in physical or chemical interaction between each of the components of the feed gas stream and the membrane material, causing one of the feed gas components to permeate through the membrane faster, via solution-diffusion, than the other components.

Gas absorption membranes. These are porous, hydrophobic membranes that transfer of selective components between the feed gas and an absorption liquid, typically a primary amine. The membrane itself does not contribute to the separation but acts as a gas-permeable barrier between the absorbent and feed gas.

CO2 CAPTURE SEGMENT OFFERS HUGE POTENTIAL

According to Hanft, membranes for CO2 capture could grow from a business worth hundreds of millions a year to a market worth tens of billions, if researchers can lower the cost, scale up the technology and insure membrane durability. The lowest estimated cost to capture and store a ton of CO2 is about $50.

“Currently, membrane systems remove CO2 at a cost of about $40 to $45 per ton, not including transportation and storage costs, which add another $15 per ton,” Hanft says. “Membranes, however, are an area of intense research as a possible game-changing technology that could lower carbon capture cost into the $10 to $20 per ton range. Additional benefits could include a small footprint system and a modular design that permits flexible operation.”

She adds that depending on selectivity, multiple membrane stages may be needed to obtain sufficiently high CO2 purity. The major challenges for membranes in post combustion capture applications stems from potential fouling of the membrane with particulate matter, uncertainty about the performance and cost of large-scale vacuum pumps and compressors, and integration of the process into power plants.

NEW MEMBRANE PRODUCTS ON CUSP OF COMMERCIALIZATION

Hanft notes that several new membrane products for gas separation appear to be on the brink of commercialization.

“After years of lacking suitable materials for large and promising applications in several areas, inorganic and organic/inorganic hybrid membranes are poised to enter the market for such uses as hydrogen separation and natural gas purification,” she says. “Pervaporation also appears to be on the verge of widespread success for a number of lucrative uses in fuels manufacturing and refinery processes.”

The combined U.S. market for membranes used in liquid and gas separating applications was worth approximately $2.2 billion in 2013, and is forecast to grow at a compound annual growth rate (CAGR) of 7.9% during the five-year period from 2014 to 2019.