Nov 22, 2015

The three-dimensional (3D) printing industry is soaring, especially in the aerospace industry. Earlier this month, a team of engineers unveiled the world’s first 3D-printed jet-powered unmanned aerial vehicle (UAV). The 33-pound high-speed aircraft, which has a 9-foot wingspan, can achieve speeds exceeding 150 mph.

Engineers from both Stratasys Ltd., a 3D printing company, and Aurora Flight Sciences, an aviation and aeronautics research company, designed and manufactured 80% of the vehicle using 3D printing technology.

“A primary goal for us was to show the aerospace industry just how quickly you can go from designing to building to flying a 3D printed jet-powered aircraft,” says Dan Campbell, an aerospace research engineer with Aurora. “To the best of our knowledge, this is the largest, fastest, and most complex 3D printed UAV ever produced.”

WHAT IS 3D PRINTING?

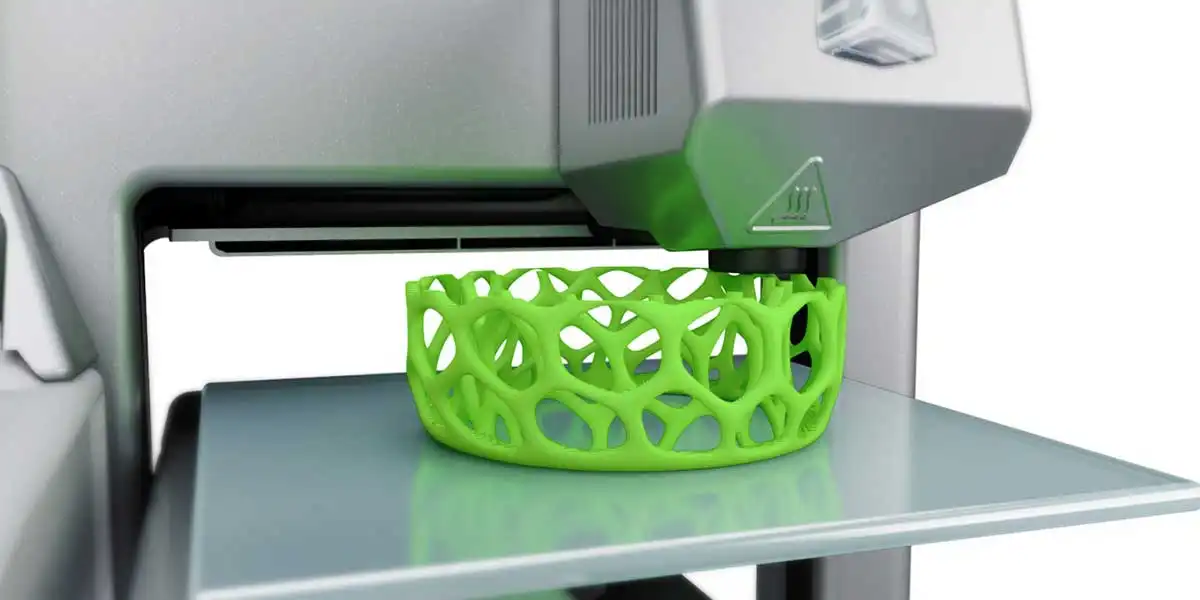

3D printing, also known as additive manufacturing, is the process of making a solid three dimensional objects of virtually any shape from a digital model, according to Andrew McWilliams, a BCC Research analyst. He explains this is achieved using specially formulated additives like plastics that are formed into successive layers of material typically laid down on a platform in different shapes. Additives can be a liquid, powder or sheet material that is cured by heat, ultraviolet (UV) light, a chemical reaction or another method.

The technology has applications primarily in aerospace, automotive, consumer goods, medical and dental sectors, Williams says. “Aerospace engineers make extensive use of 3D printed thermoplastics for concept modeling and prototyping. More recently, they have started using these materials for tooling and part manufacturing. 3D printed thermoplastics are beginning to make their way out of design studios and engineering labs and into actual end-user parts production. The 3D printed UAV produced by Stratasys/Aurora is an example of that.”

DESIGN AND BUILD TIME CUT BY 50% USING 3D PRINTING TECHNOLOGY

In producing their 3D aircraft, the engineers of the two companies used different printing techniques such as filament extrusion, laser sintering, and laser melting technology. For example, they elected to laser sinter the nylon fuel tank and 3D printed in metal their thrust vectoring exhaust nozzle to withstand the extreme heat at the engine nozzle.

The printing technology used by the team supported rapid design iterations that led to a dramatically shortened timeline from the initial concept to the first successful flight. Overall, the technology cut the design and build time of the aircraft by 50%.

The collaborative effort demonstrates the unique capabilities that additive manufacturing and 3D printing materials can bring to aerospace designers and manufacturers. The printing process allows the designers to customize certain elements of the craft for improved functionality, while the additive manufacturing enables the team develop a customized or “mission-specific vehicle” without the cost constraints of low-volume production.

The project achieved a critical need highly sought not only by the aerospace industry, but also by many industries: the need to constantly reduce weight, according to Scott Sevcik, a Stratasys development manager.

"Whether by air, water or on land, lightweight vehicles use less fuel. This enables companies to lower operational costs, as well as reduce environmental impact,” Sevcik says. “In addition, using only the exact material needed for production is expected to reduce acquisition cost by eliminating waste and reducing scrap and recycling costs.”

BCC Research estimates the total global market for 3D printing materials at $245 million in 2013. This figure is expected to rise to $285 million in 2014 and $650 million in 2019, reflecting a five-year compound annual growth (CAGR) of 17.9% over the next five years.

Biophotonics: Technologies and Global Markets (PHO024B)

Global Trade: A Strategic Shift The global trade environment is undergoing a dra...

The global demand for cutting-edge materials continues to rise, and at the foref...

We are your trusted research partner, providing actionable insights and custom consulting across life sciences, advanced materials, and technology. Allow BCC Research to nurture your smartest business decisions today, tomorrow, and beyond.

Contact UsBCC Research provides objective, unbiased measurement and assessment of market opportunities with detailed market research reports. Our experienced industry analysts assess growth opportunities, market sizing, technologies, applications, supply chains and companies with the singular goal of helping you make informed business decisions, free of noise and hype.