Jun 20, 2016

Blog Life Sciences 3D Printing Takes on New Connotations

What if there were no more long waits for an organ transplant? Instead of hoping for a donor match, what if an organ could be bioprinted? Luckily, it’s not as futuristic as it might sound. That’s good news, because according to the United Network for Organ Sharing, more than 121,000 Americans are wait listed for an organ.

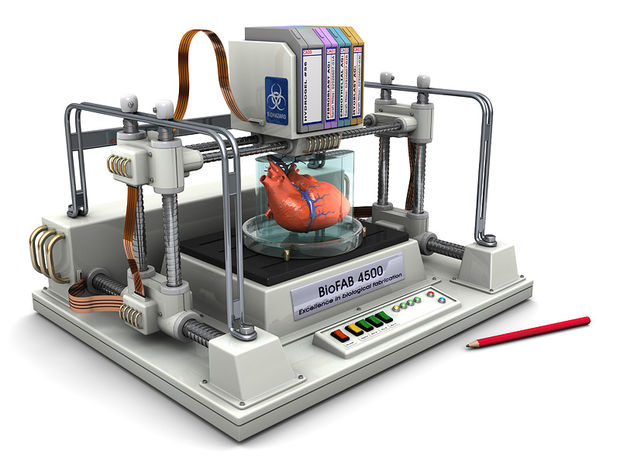

Models generated by 3D printers are already being used by some doctors as teaching aids, e.g., to make diagnoses or to practice complicated surgeries. But the utility of these printers can transcend didactic purposes to become bona fide solutions for patients. The advent of bioprinters, which use “bioink” made of replica human tissue, has brought 3D printing to a whole new level. The first bioprinted organs are being created with the aim to transplant them into humans, as will be further described below.

PRINTED LIVER TISSUE IS HERE

What if medical research could be performed with tissues that are bioprinted just for that purpose, instead of using animal models and human subjects? It’s no longer a hypothetical question.

San Diego-based Organovo unveiled its 3D-bioprinted human liver tissue for scientific research. As reported by CBC, Organovo hopes the printed liver will lead to the development of better, safer drugs faster and less expensively than when only animal and human testing was possible, said Michael Renard, the company's executive vice president of commercial operations. At the moment, only liver tissue is available for testing, but the company expects to release other printed tissue, including kidney, skin, lung, and blood vessel as well as bone, Renard said.

Organovo's exVive3D Human Liver Tissue assay tests the toxicity of medicines on 3D-printed liver tissue. Before running a costly Phase I trial with the possibility of adverse events in patients, drug developers could use the exVive3D system to test for liver toxicities in advance. The company is attempting to develop tissues that could be transplanted into a real patient. Bioprinted organs don’t necessarily have to look like the real thing, as long as they perform the proper function. That could be achieved, said Renard, through "some form of patch" that is made of tissue that could be implanted to assist the failing area.

BIOPRINTED ORGANS FOR TRANSPLANT

Scientists at the Wake Forest Institute for Regenerative Medicine (Winston-Salem, NC) have already grown a whole vaginal organ that was later transplanted into a patient who was born without one. This particular organ was built by hand. But lab director Dr. Anthony Atala said they have been experimenting with bioprinters for more than a decade to speed up the creation process. As mentioned above, easily producible kidneys, lungs, and hearts could speed up lengthy wait times for patients on organ donation lists.

A major challenge with bioprinting organs to transplant into humans is that scientists must be able to make blood vessels that are capable of keeping blood flowing to them. Wake Forest’s approach mixes live cells with a gel that starts out as a liquid but quickly hardens to the consistency of living tissue, and layers them in with tiny tunnels that serve as passages for nutrients to feed the cells until blood vessels can grow in and do the job naturally (see NBC News story). Wake Forest researchers have grown muscle, ears, and jawbones. The team is working to print out livers, lung tissue, and kidney tissue.

In Nature Biotechnology, the team described its integrated tissue-organ printer (ITOP), which can fabricate stable, human-scale tissue constructs of any shape. Atala's team started out with actual inkjet printers, but they've now developed customized devices. As the cells are printed, microchannels are created. Within 24 hours, blood vessels start to sprout in these channels. The resulting bioink is a mixture of polymers, living cells, and the nutrients they need. Atala hopes this technology will eventually be a way for people to get custom-made transplants using their own cells, or closely matched cells, grown to just the right size and shape.

BIOPRINTING JOINS THE FIGHT AGAINST ALZHEIMER'S

As described in Biomaterials, researchers from the University of Wollongong in Australia and the University of Texas at Dallas are using bioprinting to create a 3D picture of the human brain. They created a bioink using gellan gum, which they combined with brain cells. They found that the gellan gum helped the brain cells grow well and function as a network—much like in a real brain.

Professor Gordon Wallace, an author on the paper, suggested: “The advent of 3D printing in recent years and the ability to create structures containing materials, and even living cells, gives us that ability to start to probe some very fundamental questions. It lets us build structures that have more real-world applications.” Wallace continued: “The brain is enormously complex and so are neurodegenerative diseases. Looking at what’s going on in 3D—in a similar structure to the real human brain—will give us a much better idea of the biology behind these diseases, and help researchers working on ways to treat them.”

This October, Professor Wallace, as well as researchers from the Wake Forest Institute for Regenerative Medicine, are included among those who will be presenting their advances at an upcoming bioprinting conference in Boston (BioPrinting: Beyond the Scaffold).

In today’s fast-paced biomedical world, researchers and pharmaceutical companies...

Radiopharmaceuticals represent a cutting-edge frontier in modern medicine, offer...

Implantable Remote Patient Monitoring (IRPM) devices are revolutionizing healthc...

We are your trusted research partner, providing actionable insights and custom consulting across life sciences, advanced materials, and technology. Allow BCC Research to nurture your smartest business decisions today, tomorrow, and beyond.

Contact UsBCC Research provides objective, unbiased measurement and assessment of market opportunities with detailed market research reports. Our experienced industry analysts assess growth opportunities, market sizing, technologies, applications, supply chains and companies with the singular goal of helping you make informed business decisions, free of noise and hype.