Jul 15, 2024

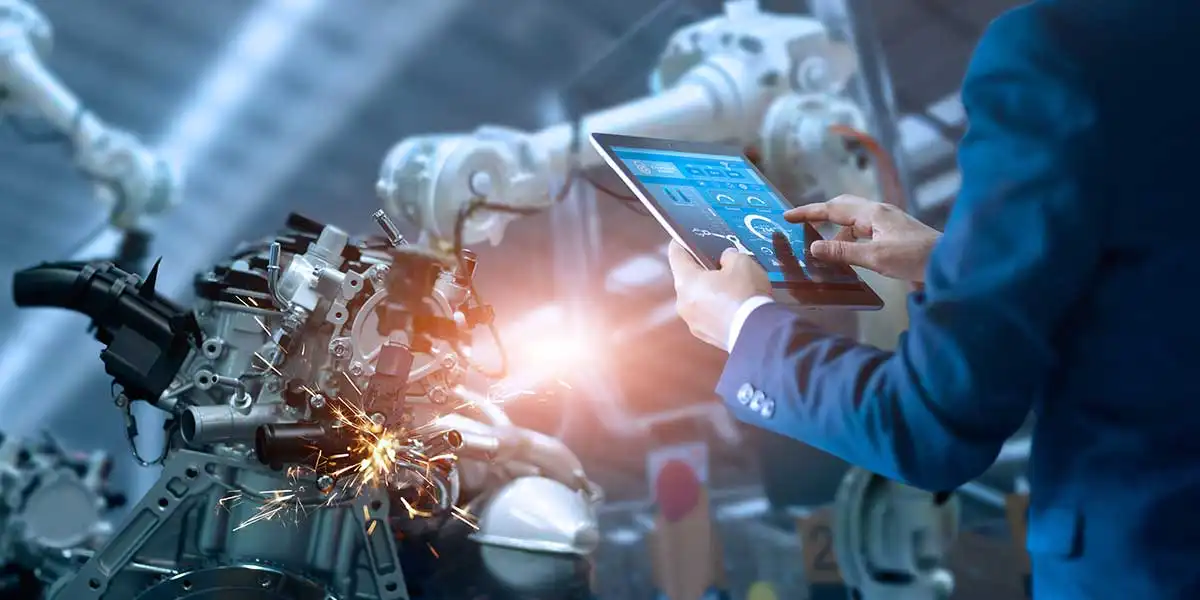

Blog Digital World 10 Ways Industrial IoT is Transforming Modern Manufacturing

Manufacturing is undergoing a revolution thanks to the Industrial Internet of Things (IIoT), which is bringing about a number of important developments and enhancements. These are ten significant ways that IIoT is changing contemporary manufacturing:

According to BCC Research, The global market for IIoT is estimated to increase from $147.2 billion in 2023 to reach $391.8 billion by 2028, at a compound annual growth rate (CAGR) of 21.6% from 2023 through 2028.

The global market for IIoT is estimated to increase from $147.2 billion in 2023 to reach $391.8 billion by 2028, at a compound annual growth rate (CAGR) of 21.6% from 2023 through 2028.

In order to track the condition of equipment and anticipate possible breakdowns before they occur, predictive maintenance makes use of IIoT sensors and data analytics. As a result, machinery has less downtime, requires less maintenance, and lasts longer.

Example: Rolls-Royce employs IIoT in its airplane engines to track performance and only arrange repairs when required.

IIoT makes it possible to track and monitor shipments and inventory in real time. As a result, there are fewer stockouts or overstock scenarios, better demand forecasts, and increased supply chain visibility.

Example: DHL's SmartSensor technology keeps an eye on the humidity and temperature of delicate goods to prevent losses and guarantee product quality.

IIoT assists in locating bottlenecks and inefficiencies by gathering and evaluating data from several manufacturing phases. Manufacturers can increase overall productivity, optimize resource allocation, and streamline procedures.

Example: The Amberg Electronics Plant of Siemens uses IIoT to almost fully automate its processes, which leads to extremely effective manufacturing operations.

By continuously monitoring production parameters, IIoT sensors and powerful analytics guarantee consistent product quality. It is possible to quickly identify and fix deviations from the norm.

Example: Harley-Davidson using the Internet of Things (IIoT) to track each stage of their manufacturing process, guaranteeing superior quality and minimizing errors. cutting down on errors.

By monitoring and optimizing energy usage, IIoT assists manufacturers in cutting waste and advancing sustainable practices. This reduces the environmental impact while simultaneously lowering operating costs.

Example: The EcoStruxure platform from Schneider Electric leverages IIoT to assist companies in maximizing their energy use and achieving sustainability objectives.

IIoT devices can keep an eye on the working environment and the health of workers, sending out alerts and delivering data-driven insights to improve workplace safety and avoid accidents.

Example: With the use of wearable technology, Honeywell's Connected Worker solution keeps an eye on employees' vital signs and the surrounding circumstances to protect them in dangerous situations.

Thanks to the real-time asset tracking offered by IIoT, producers can always be certain of the precise location and status of their goods and equipment. This lowers losses and enhances asset usage.

Example: GE's Asset Performance Management (APM) software facilitates industry-wide asset tracking and management, guaranteeing peak performance.

Through the use of IIoT, manufacturing processes may be remotely monitored and controlled, giving operators global access to production lines and equipment. In the increasingly worldwide market of today, this flexibility is extremely valuable.

Example: With ABB's Ability platform, industrial activities can be remotely monitored and managed, increasing productivity and reaction times.

Better integration and communication between various departments and systems within a manufacturing organization are made possible by IIoT. Better collaboration, data exchange, and coordinated activities result from this.

Example: With Bosch's IoT suite, different production processes are integrated, facilitating department-to-department communication and data exchange.

IIoT creates opportunities for creative business models like Equipment-as-a-Service (EaaS), in which users pay for the usage of equipment rather than purchasing it altogether based on performance criteria.

Example: By using IIoT to track usage and performance, Kaeser Compressors provides customers with a dependable and effective air supply without requiring ownership.

A new era of manufacturing is being driven by the Industrial Internet of Things, and it will be marked by increased productivity, higher quality, and creative business models. IIoT will surely bring about even more revolutionary changes to the industry as it develops, assisting manufacturers in remaining competitive in a market that is becoming more complex and dynamic by the day.

Consider becoming a member of the BCC Research library and gain access to our full catalog of market research reports in your industry. Not seeing what you are looking for? We offer custom solutions too, including our new product line: Custom Intelligence Services.

Contact us today to find out more.

Sandeep is a Senior Executive in Marketing Operations at BCC Research, proficiently serving as a graphic designer and content creative specialist. His expertise extends to AutoCAD and Revit, and he has made valuable contributions to the event industry with his design skills.

From smartphones to satellites, antennas play a vital role in enabling the seaml...

Introduction Artificial Intelligence (AI) and the Internet of Things (IoT) are r...

We are your trusted research partner, providing actionable insights and custom consulting across life sciences, advanced materials, and technology. Allow BCC Research to nurture your smartest business decisions today, tomorrow, and beyond.

Contact UsBCC Research provides objective, unbiased measurement and assessment of market opportunities with detailed market research reports. Our experienced industry analysts assess growth opportunities, market sizing, technologies, applications, supply chains and companies with the singular goal of helping you make informed business decisions, free of noise and hype.