Rising consumer demand for flavor and fragrance products has spurred market players to launch a variety of new and innovative products to better position themselves in the global market for flavors and fragrances.

Manus Bio, an industrial biotech start-up,

recently announced its entry into the market on the heels of its low-cost process for engineering microbes with complex metabolic pathways borrowed from plants. The reprogrammed microbes can produce an array of rare and expensive ingredients used to manufacture flavors, fragrances, and other products.

The

microbial platform, which uses advanced fermentation technology as its process, allows for more control in identifying and extracting compounds along the metabolic pathway, which could lead to discoveries of new compound ingredients.

Last year, the Massachusetts-based Manus Bio recreated a natural plant process in microbes to cheaply produce mass quantities of a coveted stevia plant compound for a zero-calorie sweetener. The product is much sweeter than today’s commercial alternatives. In nature, only .01% of the compound can be extracted from the stevia plant, which yields a more abundant, but bitter compound.

But Manus Bio engineered bacteria to mimic the stevia plant’s metabolic pathway. When put through the company's fermentation process, the bacteria produced the compound at greater than 95% purity. The company touts the process as efficient, low-cost, and scalable, making it commercially viable for the food and beverage markets.

REFINED FLAVORS AND NEW PRODUCTS AT LOW COST

Manus Bio's commercial fermentation process involves engineering microbes with plant metabolic pathways, and placing them into large-scale fermenters with inexpensive sugars to feed on. While fermenting, the microbes produce large amounts of the ingredients that can be extracted with commercial processes. Manus plans to scale up to commercial levels this year and sell the products to their industrial partners.

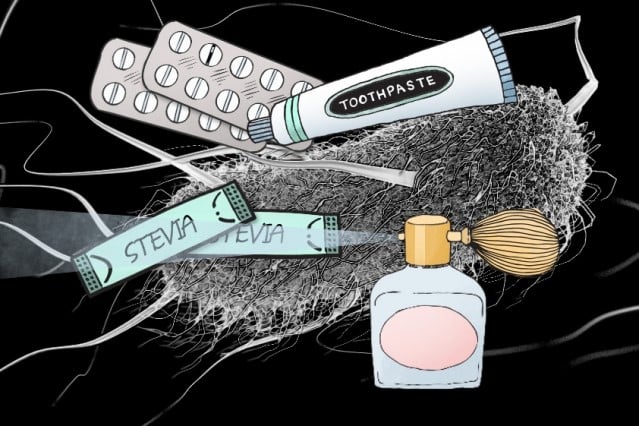

The company's production of the new sweetener demonstrates how its microbial engineering can be used to make noncaloric beverages, perfumes, toothpastes, detergents, pesticides, and even therapeutics, among other products.

Manus Bio's process averages about one-tenth the cost of any plant-extraction method while significantly reducing use of land resources, notes MIT professor Gregory Stephanopoulos, who co-invented the core technology.

“If you take the original compound from the stevia plant, it has a metallic taste. But if you isolate the components of the metabolic pathway and find individual compounds, then you end up with the product of the highest interest,” says Stephanopoulos, who also is co-founder of Manus Bio and serves as its scientific advisor.

MORE THAN 'SLAPPING GENES TOGETHER'

Fermenting engineered microbes to produce certain compounds has become a common process in the industry. But the key to Manus Bio's process is engineering the pathway to produce sufficient quantities of those compounds, which makes it commercially attractive.

“Slapping genes together to make a product is fine, but this doesn’t give you a platform for producing something economically,” Stephanopoulos

says. “There’s a big jump between making a few milligrams of a compound and a few grams, which is what you need to make it commercially viable.”

The technology also offers a platform “that can aid in the discovery of new molecules,” says CEO Ajikumar Parayil. He explains that in nature, for instance, a compound extracted from a plant represents the end product of long, complex metabolic processes with many intermediate steps. Currently, there’s no way to discover all the compounds produced along the way.

However, Manus Bio can monitor the entire metabolic pathway and identify, tweak, and potentially extract previously untested compounds produced at any stage. In doing so, “you multiply incredibly the number of chemicals that may have very important properties as, say, pharmaceuticals, flavors, and pesticides,” Stephanopoulos says. But that’s further down the road, he adds.

The company is currently ramping up production for commercialization of the sweetener and other products.

The global market for flavors and fragrances, which has grown exponentially in the past few years, should continue its rapid growth, predicts BCC Research in its report,

Global Markets for Flavors and Fragrances . Changing consumer lifestyle and significant technological advances should lead the market to a $37.0 billion valuation in 2021 at a five-year CAGR of 6.4%.