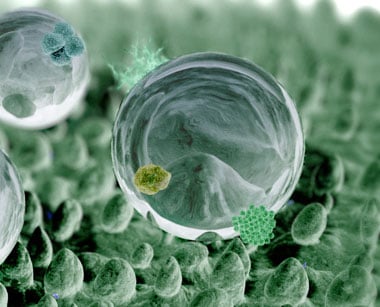

Nanotechnology advances in recent years have paved the way for the development of smart textiles like water-repellent fabrics. Recently, Australian scientists developed a new method of growing nanostructures on textiles that, when exposed to light, spontaneously clean themselves by degrading organic matter.

Researchers from Melbourne-based RMIT, a public university of technology, design, and enterprise, worked with copper and silver-based nanostructures, which are known for their ability to absorb visible light.

When exposed to light, the nanostructures receive a “hot electron” energy boost, says Rajesh Ramanathan, a researcher with RMIT’s Ian Potter NanoBioSensing Facility and NanoBiotechnology Research Lab.

“There is a concept called ‘hot electron,’--when these metals absorb light, they are able to excite themselves and in the process, when they get excited, they are able to clean themselves,” Ramanathan told

Kemal Atlay. “So [the textiles] are able to degrade any organic matter on them.”

WHAT ARE HYDROPHOBIC COATINGS?

Hydrophobic coatings are thin layers of waterproof substances on substrates. Also known as water-repellent coatings because of their ability to repel water, hydrophobic coatings have a surface contact angle of 90 degrees to 150 degrees, while coatings that have a surface contact angle of more than 150 degrees are called superhydrophobic coatings,

according to BCC Research analyst Aneesh Kumar.

“Hydrophobic coatings were derived from the lotus effect, which refers to the high water repellency of the leaves of lotus flower,” Kumar explains. “Hydrophobic coatings are thin layers of waterproof substances on substrates. The coatings work on the principle of reduced contact area and adhesion force between the surface and water droplets, which leads to the coated surface repelling water.”

Self-cleaning, anti-fouling, de-icing and anti-icing, anti-microbial, anti-corrosion and drag reduction are among the major properties exhibited by hydrophobic and superhydrophobic coatings. These properties provide increased life spans for substrates, reduced maintenance costs and better functionality of products.

HYDROPHOBIC COATING APPLICATIONS

Hydrophobic and superhydrophobic coatings have applications in various end-user industries such as building and construction, automobiles, aerospace and defense, marine, electronics, medical devices, optometry, textiles and power and energy. Superhydrophobic surfaces are used in applications such as self-cleaning and non-wetting coatings of fabrics, anti-fogging, anti-icing and drag reduction.

Hydrophobic and superhydrophobic coatings are used on a wide range of substrates that include glass, steel, concrete, wood, leather, polymers, fur, and fabric.

TEXTILES MARKET FOR HYDROPHOBIC COATINGS

Hydrophobic coatings for textiles have extremely low surface energy and a nano-structure, which creates a superhydrophobic property, explains Kumar. Hydrophobic coatings are applied to the outside surface of textiles primarily because of their quick drying, sunlight resistant, anti-abrasion and thermal conductivity properties. This leads to an outside surface with moisture repelling properties, he says.

Hydrophobic coatings for textile are ideally applied on fine cottons, silk, linen, wool and other fine fabrics. Kumar says that hydrophobic coating of textiles offers the following benefits: easy to clean, high penetration into fibers, which causes the nano-particles to cover all fibers, and preservation of the color of the coated textile surface.

NOVEL APPROACH FOR GROWING NANOSTRUCTURES

The study published in

Advanced Materials Interfaces, describes how RMIT team grew the nanostructures directly onto the textiles by dipping them into a few solutions, resulting in the development of stable nanostructures within 30 minutes.

When exposed to light, it took less than six minutes for some of the nano-enhanced textiles to spontaneously clean themselves.

“Our next step will be to test our nano-enhanced textiles with organic compounds that could be more relevant to consumers, to see how quickly they can handle common stains like tomato sauce or wine,” Ramanathan said.

He hopes the technology will also be picked up by agriculture and pharmaceutical industries as it provides a more efficient way of using copper in chemical reactions.

“A lot of these industries actually use copper-based catalysts,” Dr Ramanathan said. “Generally what happens in these industries, when they use the copper [in a reaction], the copper cannot be reused.

“So technically you will reduce costs in the long run because you can reuse your textile a number of times.”

Kumar anticipates the market for hydrophobic and superhydrophobic coatings in the textile market to grow at a five-year compound annual growth rate (CAGR) of 8.8% to reach $46.7 million in 2020. He anticipates increasing demand for hydrophobic and superhydrophobic coatings for protective

clothing, swimming and diving clothes, and smart textiles to drive the market through 2020.